|

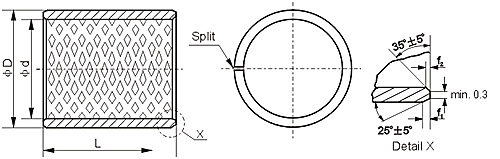

| FB090 Bronze rolled bearings |

| MATERIAL STRUCTURE |

|

|

basic characteristic |

| This shaft sleeve is an economical bearing with high load-bearing capacity and good wear resistance, rolled with CuSn6.5P0.1 or CuSn8P0.3 bronze as the base material. The working surface of the standard FB090 product is covered with regular diamond shaped oil holes, which serve as oil storage and can easily form an oil film during initial movement, thereby reducing the initial friction coefficient. |

| main parameter TECHNICAL DATE |

|

Maximum load capacity

|

Static bearing capacity

|

120N/mm2

|

|

Hardness

|

HB 90-120

|

| |

Dynamic bearing capacity

|

40N/mm2

|

|

Elongation rate

|

40%

|

|

Maximum linear speed

|

|

2m/s

|

|

Operating temperature

|

-100℃~+200℃

|

|

Maximum PV

|

|

2.8N/mm2.m/s

|

|

friction coefficient

|

0.08~0.25

|

|

Tensile strength

|

|

450N/mm2

|

|

Thermal conductivity coefficient

|

60W(m.K)-1

|

|

Yield strength

|

|

250N/mm2

|

|

Linear expansion coefficient

|

15x10-6K

|

|

| APPLICATION CHARACTER |

1. The inner holes of this product are filled with diamond shaped oil pits, which can store a large amount of grease during use and extend the refueling interval

2. Low oil lubrication, suitable for situations that are difficult to lubricate with oil or water

3. Good wear resistance, small friction coefficient, and long service life

4. Can be used within the range of -100 ℃ -200 ℃

5. Good running performance, low noise, and no pollution

6. Thin walled structure, lightweight, can reduce mechanical volume

7. The matrix has high density, no air shrinkage pores, and high load-bearing capacity

At present, it has been widely used in various sliding parts of machinery, such as: automatic mechanical equipment (telescopic, swinging, sliding, bending, turning, rotating parts) hydraulic cylinder guide sleeve, textile machinery, plastic molding machine, die-casting machine, rubber machinery, hydraulic transport vehicles, locomotives, motorcycle industry, ports, water conservancy, engineering, agricultural machinery, etc. |

|

|

|

|

FB090 Standard bearing size

|

|

|

|

d

|

D

|

f1

|

f2

|

L 0

-0.40

|

|

10

|

15

|

20

|

25

|

30

|

35

|

40

|

50

|

60

|

70

|

80

|

90

|

100

|

|

10

|

12

|

0.5

|

0.3

|

1010

|

1015

|

1020

|

|

|

|

|

|

|

|

|

|

|

|

12

|

14

|

1210

|

1215

|

1220

|

|

|

|

|

|

|

|

|

|

|

|

14

|

16

|

1410

|

1415

|

1420

|

1425

|

|

|

|

|

|

|

|

|

|

|

15

|

17

|

1510

|

1515

|

1520

|

1525

|

|

|

|

|

|

|

|

|

|

|

16

|

18

|

1610

|

1615

|

1620

|

1625

|

|

|

|

|

|

|

|

|

|

|

18

|

20

|

1810

|

1815

|

1820

|

1825

|

|

|

|

|

|

|

|

|

|

|

20

|

23

|

0.8

|

0.4

|

2010

|

2015

|

2020

|

2025

|

|

|

|

|

|

|

|

|

|

|

22

|

25

|

2210

|

2215

|

2220

|

2225

|

2230

|

|

|

|

|

|

|

|

|

|

24

|

27

|

|

2415

|

2420

|

2425

|

2430

|

|

|

|

|

|

|

|

|

|

25

|

28

|

|

2515

|

2520

|

2525

|

2530

|

|

|

|

|

|

|

|

|

|

28

|

31

|

|

2815

|

2820

|

2825

|

2830

|

|

|

|

|

|

|

|

|

|

30

|

34

|

1.0

|

0.6

|

|

3015

|

3020

|

3025

|

3030

|

3035

|

3040

|

|

|

|

|

|

|

|

32

|

36

|

|

3215

|

3220

|

3225

|

3230

|

3235

|

3240

|

|

|

|

|

|

|

|

35

|

39

|

|

3515

|

3520

|

3025

|

3530

|

3535

|

3540

|

|

|

|

|

|

|

|

40

|

44

|

|

|

4020

|

4025

|

4030

|

4035

|

4040

|

4050

|

|

|

|

|

|

|

45

|

50

|

1.2

|

0.8

|

|

|

4520

|

4525

|

4530

|

4535

|

4540

|

4550

|

|

|

|

|

|

|

50

|

55

|

|

|

5020

|

5025

|

5030

|

5035

|

5040

|

5050

|

5060

|

|

|

|

|

|

55

|

60

|

|

|

5520

|

5525

|

5530

|

5535

|

5540

|

5550

|

5560

|

|

|

|

|

|

60

|

65

|

|

|

|

6025

|

6030

|

6035

|

6040

|

6050

|

6060

|

6070

|

|

|

|

|

65

|

70

|

|

|

|

|

6530

|

6535

|

6540

|

6550

|

6560

|

6570

|

|

|

|

|

70

|

75

|

|

|

|

|

7030

|

7035

|

7040

|

7050

|

7060

|

7070

|

7080

|

|

|

|

75

|

80

|

|

|

|

|

7530

|

7535

|

7540

|

7550

|

7560

|

7570

|

7580

|

|

|

|

80

|

85

|

1.4

|

0.8

|

|

|

|

|

8030

|

8035

|

8040

|

8050

|

8060

|

8070

|

8080

|

|

|

|

85

|

90

|

|

|

|

|

8530

|

8535

|

8540

|

8550

|

8560

|

8570

|

8580

|

8590

|

|

|

90

|

95

|

|

|

|

|

9030

|

9035

|

9040

|

9050

|

9060

|

9070

|

9080

|

9090

|

|

|

95

|

100

|

|

|

|

|

|

|

9540

|

9550

|

9560

|

9570

|

9580

|

9590

|

95100

|

|

100

|

105

|

|

|

|

|

|

|

|

10050

|

10060

|

10070

|

10080

|

10090

|

100100

|

|

105

|

110

|

|

|

|

|

|

|

|

10550

|

10560

|

10570

|

10580

|

10590

|

105100

|

|

110

|

115

|

|

|

|

|

|

|

|

11050

|

11060

|

11070

|

11080

|

11090

|

110100

|

|

d

|

D

|

f1

|

f2

|

L 0

-0.40

|

|

25

|

30

|

35

|

40

|

50

|

60

|

70

|

80

|

90

|

100

|

|

115

|

120

|

1.4

|

0.8

|

|

|

|

|

11550

|

11560

|

11570

|

11580

|

11590

|

115110

|

|

120

|

125

|

|

|

|

|

|

12060

|

12070

|

12080

|

12090

|

120110

|

|

125

|

130

|

|

|

|

|

|

12560

|

12570

|

12580

|

12590

|

125110

|

|

130

|

135

|

|

|

|

|

|

13060

|

13070

|

13080

|

13090

|

130110

|

|

135

|

140

|

|

|

|

|

|

13560

|

13570

|

13580

|

13590

|

135110

|

|

140

|

145

|

|

|

|

|

|

14060

|

14070

|

14080

|

14090

|

140110

|

|

145

|

150

|

|

|

|

|

|

14560

|

14570

|

14580

|

14590

|

145110

|

|

150

|

155

|

|

|

|

|

|

15060

|

15070

|

15080

|

15090

|

150110

|

|

155

|

160

|

|

|

|

|

|

15560

|

15570

|

15580

|

15590

|

155110

|

|

160

|

165

|

|

|

|

|

|

16060

|

16070 |

16080

|

16090

|

160110

|

|

165

|

170

|

|

|

|

|

|

16560

|

16570

|

16580

|

16590

|

165110

|

|

170

|

175

|

|

|

|

|

|

17060

|

17070

|

17080

|

17090

|

170110

|

|

175

|

180

|

|

|

|

|

|

17560

|

17570

|

17580

|

17590

|

175110

|

|

180

|

185

|

|

|

|

|

|

18060

|

18070

|

18080

|

18090

|

180110

|

|

185

|

190

|

|

|

|

|

|

18560

|

18570

|

18580

|

18590

|

185110

|

|

190

|

195

|

|

|

|

|

|

19060

|

19070

|

19080

|

19090

|

190110

|

|

195

|

200

|

|

|

|

|

|

19560

|

19570

|

19580

|

19590

|

195110

|

|

200

|

205

|

|

|

|

|

|

20060

|

20070

|

20080

|

20090

|

200110

|

|

|